3D Printing. ABS plastics.

3D Printing & rapid prototyping in real ABS. The corner stone of our 'Strong & Durable' service.

Our ABS 3D printing material gives you a cost effective way of producing models in a material which is strong and durable but still offers good detail and surface finish.

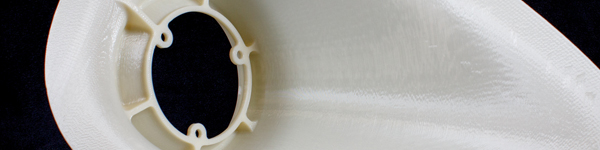

The 3D Printing process used with ABS is the FDM (Fusion Deposition modelling) process where material is heated and squeezed through a fine nozzle to build your design in 250 micron layers. The surface finish may be finely textured and slightly 'ribbed' where layers join and produces parts with robust mechanical properties, subject to your design.

In addition to the core ABS plus and ABS M30 materials we also give you derivative materials for specialist applications. ABS M30i for Medical & Biocompatible applications, ASA with high levels of UV stability and ESD7 with is static dissipative.

Strength & Durability. Affordable.

ABSplus \ ABS M30.

Our default ABS materials are ideal for rapid prototyping pre production parts & models where strength, durability or low costs are required.

ABSplus is used on our smaller machines and gives the lowest cost with the fastest turnaround.

ABS M30 is used for large format 3d printing and is also available in Black plus a range of colours.

3D Printing in ABS gives you parts with a Smooth, fine textured surface finish, 'Ivory' in colour plus High levels of accuracy and dimensional stability. Finished parts may be painted if required.

Specialist Applications. ABS.

Our 3D Printed ABS service gives you a choice of ABS derivatives so you can choose exactly the right material for your design.

M30i. BioCompatible \ Medical.

ABS-M30i works with FDM Technology to build your designs in a material that can be gamma or EtO sterilized. M30i is an engineering thermoplastic which has good mechanical strength and complies with ISO 10993 and USP Class VI. Ideal for building functional prototypes, tooling and end-use parts.

ASA. UV-Stable.

The ASA variant represents the latest material technology in FDM 3D Printing. ASA gives you a production-grade thermoplastic which combines mechanical strength and UV stability with the best aesthetics that FDM technology has to offer. UV Stability is ideal for designs you intended for outdoor use.

ESD 7. Electrostatic Dissipative.

ABS-ESD7 is a material which resists the build up of static electricity. It is ideal for applications where the build up of static and the resulting discharge need to be controlled. ESD7 is useful in environments where dust or powder could otherwise be attracted to a part through static. Our clients use ESD7 in specialist manufacturing environments, using the material to create guides, jigs and fixtures used in their manufacturing process.

ABS-CF10. Carbon Fibre reinforced ABS.

ABS-CF10 adds extra strength and durability to standard ABS with the addition of chopped carbon fibre to the material. Offering, improved strengh, good asethics and still offering excellent value of other 'Carbon' materials, ABS-CF10 is a great choice for demanding projects.

ABS. Material Properties.

Key properties for our ABS M30 3D Printing:

- Heat deflection temperature of 96c.

- Izod notched impact of upto 106 J/m

- Tensile Strength 28-32 MPa

- Default print of 0.254 (254 Micron) layers.

- Minimum recommended wall or feature thickness of 1mm

- Build volume - Maximum: 1000 x 600 x 600mm

- Build volume - Next day / economy service: 254 x 254 x 254mm

3D Printed Materials

OUR CLIENTS SAY

Outstanding communication and understanding of what customer needs. Fast dispatch with tracking service, fairly quick turnaround and getting the job done within given timescale.

"Very helpful with advice pre printing very prompt manufacture and delivery."