3D Printing Aluminium.

3D Printing in Aluminium. Strong & Durable Service.

3D print your designs in Aluminium and choose from a range of alloys to suite your application.

Aluminium is 3D printed using the DMLS (Direct Metal Laser Sintering) or SLM process. A very fine metal powder is melted with a laser to produce your design layer by layer. Once your design is complete any support structures are removed and any finishing completed. Unused powder is recycled for use on the next model.

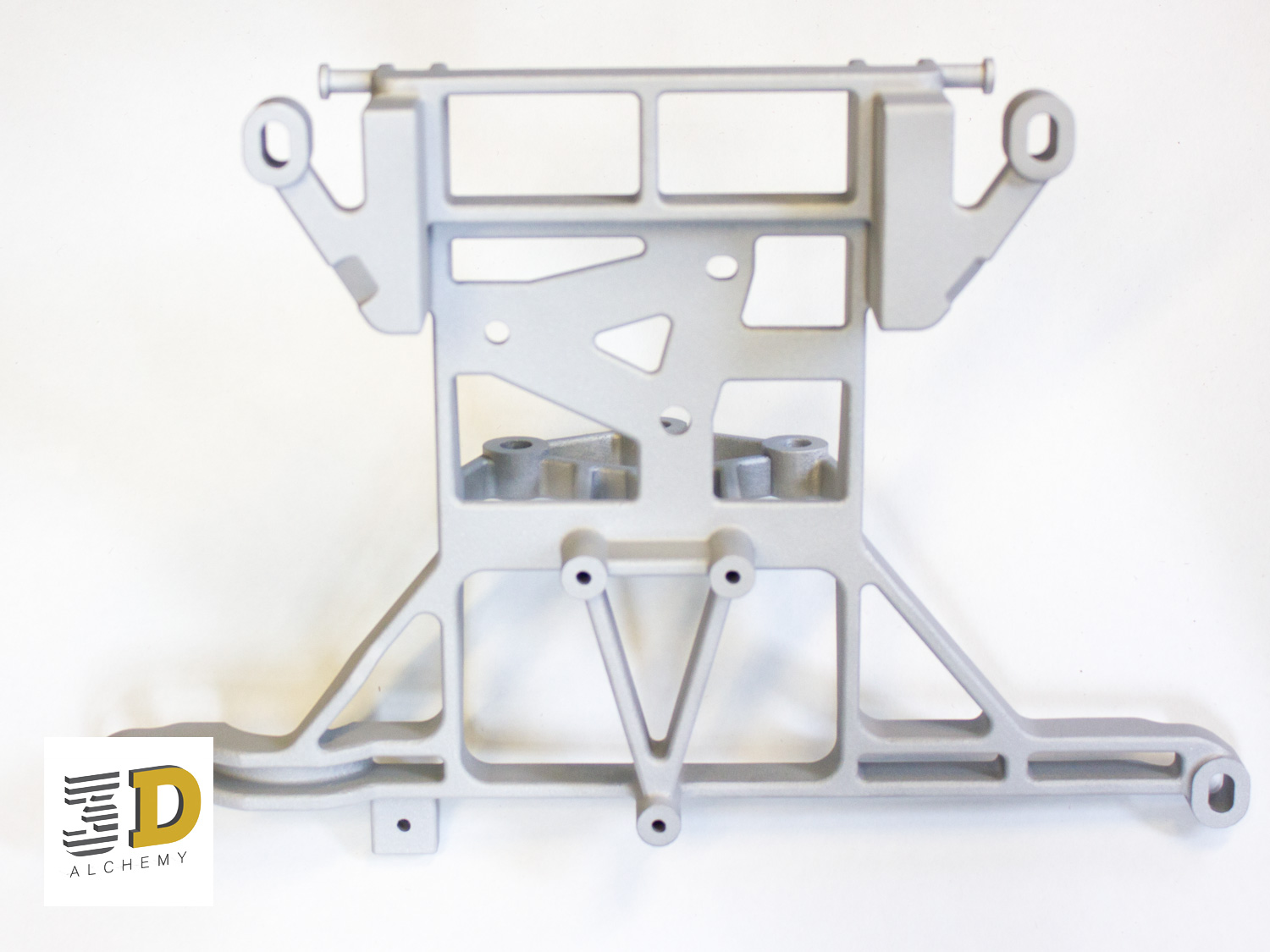

3D Printing in Aluminium can work out more cost effective than traditional 'subtractive' processes, especially where you have complex or intricate designs. Extra complexity does not add to the price of manufacture as it might with traditional manufacture.

Aluminium AlSi10Mg

AlSi10Mg is our default Aluminium material for 3d printing.

The alloy gives a homogeneous and almost pore free structure and is impermeable. AlSi10Mg offers high hardness values, and good dynamic strength. The nature of the DMLS or SLM process means that the mechanical properties of finished parts are better than traditional casting processes.

AlSi10Mg has very good corrosion resistance and good electrical conductivity, It has high dynamic toughness and excellent thermal conductivity.

Applications:

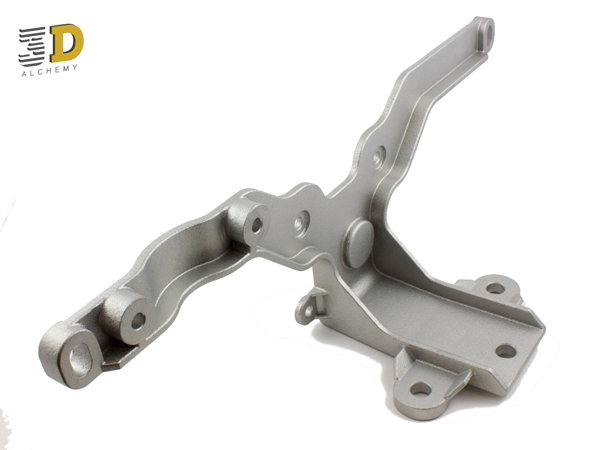

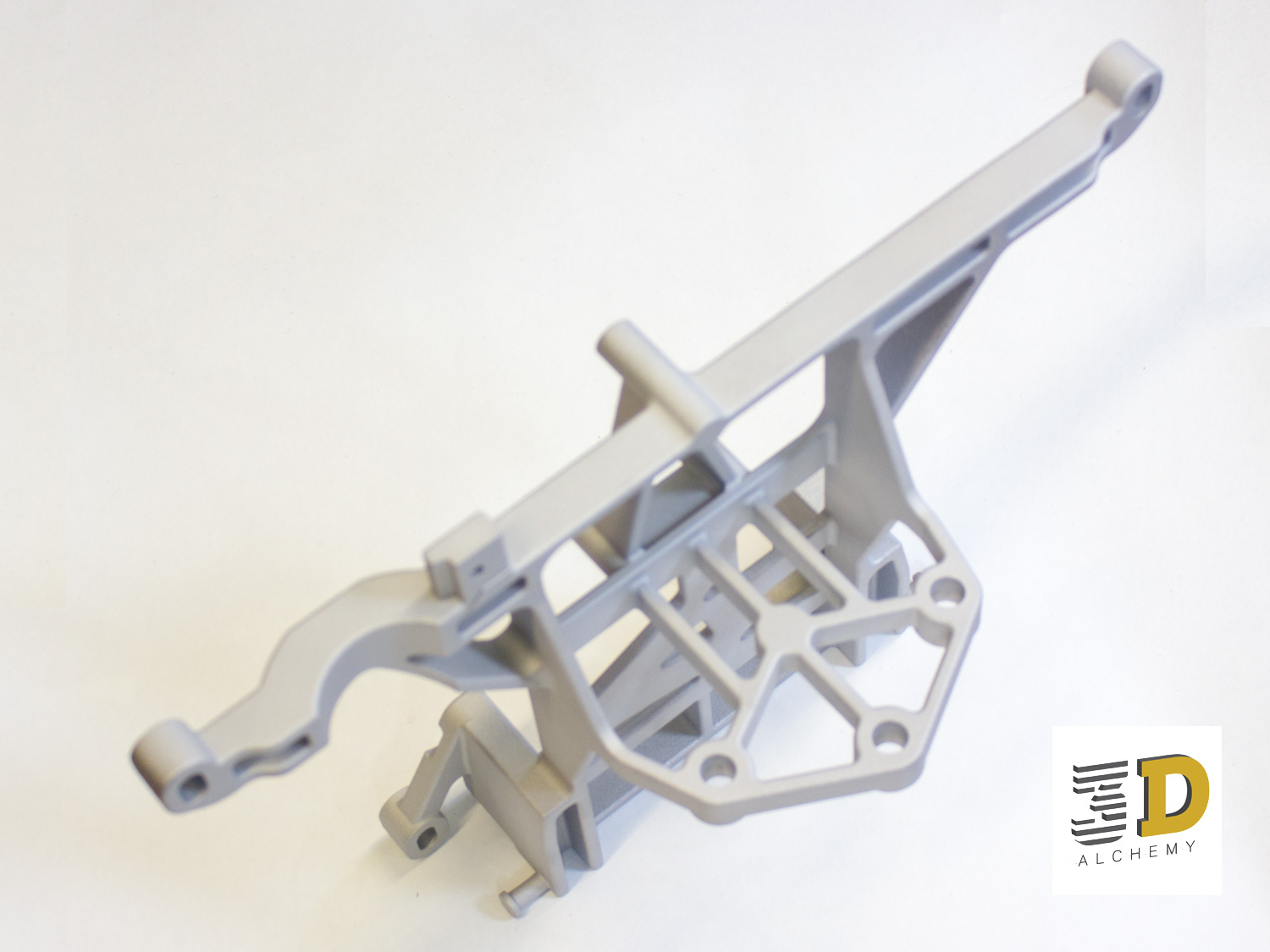

AlSi10Mg is ideal for design applications where you need good mechanical properties and low weight. Components 3d printed in the alloy can be subjected to a range of post build finishing processes, including heat-treatment, machining, welding, eroding, micro-blasting, polishing and coatings.

3d printed aluminium AlSi10Mg is an alternative to cast parts.

Aluminium AlMgSc ( Scalmalloy®RP )

AlMgSc ( Scalmalloy®RP ) has been specifically designed for aerospace applications. The specific blend of elements gives AlMgSc improved strength over traditional casting alloys.

The strength of components can be considerably increased with a precipitation hardening process, to give a performance which is twice that of T6 heat treated AlSi10Mg.

Finally, parts produced from AlMgSc may be welded and exhibit excellent corrosion resistance.

Applications:

With a strength to density ratio comparable to titanium the alloy is also very tough, making it ideal for safety critical designs.

Available 'On Request', please contact us for details.

Supporting information. 3D printing in Aluminium.

Our metal 3d printing service gives you a selection of build envelopes of up to 500mm in AlSi10Mg.

- 400 dia x 360mm - Aluminium (AlSi10Mg)

- 500 x 280 x 363mm - Aluminium(AlSi10Mg)

- 50μm typical layer thickness - depeding on machine and configuration.

Data sheets.

AlSi10Mg Aluminium Alloy Datasheet

Examples of our work.

For important technical and ordering information on our 3d printing in metals, please see our general 'Metals' page.

3D Printed Materials

OUR CLIENTS SAY

"These guys have been more than helpful in our first foray into 3D design/printing and the results were very good as a result. Recommended for a personal & knowledgeable service."

"Great company for 3D prints in wide range of materials; good turn-around from quotation to delivery. Physically accurate product and great for sample evaluation prior to any production tooling investment."