3D Printing. Rubber.

3D Printing in simulated Rubber. 'Fine Detail' service.

Our simulated Rubber 3D printing service is intended where your designs require materials with rubber like or specific tactile properties.

3D Printing in our rubber like materials using our Fine Detail service also gives you a range of Shore A values using the Polyjet Digital Materials technology. This process blends flexible and rigid materials to give a stepped range of hardness values. The Polyjet 3D printing process produces your designs with a smooth surface finish and is ideal for fit and form testing and design confirmation.

Uniquely, because the 3d-printing process blends 2 materials you can combine both rigid and flexible elements in a single build, for example to prototype over moulding and seals.

Durable. End Use.

If you need to 3D print components for 'end use' applications we suggest:

in our Strong and Durable service. We also Vac Casting service.

Different Shore A Values. Mix and Match.

Tango Black PLUS is the base flexible material with a shore A hardness value of 27. Combined with the rigid Vero White Plus material the process gives you a choice of stepped choice of Shore A values through 27, 40, 50, 60, 70, 85 & 95.

Our Fine Detail simulated Rubber 3d printing service gives you the option to produce different versions of your design in the same build, with different Shore A values, so reducing the unit price. Mix and Match Shore A values or different versions and evaluate a broader range of options for your designs.

Agilus. New and Improved simulated rubber.

The new Agilus materials offer improved strength and durability and can also be 3d printed as a digital material by mixing with a rigid polyjet materials. This gives you a more robust simulated rubber in a range for Shore A values with improved tear resistance.

3D print flexible and rigid elements in your design at the same time, and print the flexible elements in different shore A values for comparison in the same build.

We suggest Agilus where your designs have thin walls, require 'stretch' or need to survive longer with repeated flexing.

A final benefit of Agilus is better support removal, leaving your parts with a cleaner surface finish.

- Agilus 30 - translucent (FLX935)

- Agilus 30 - Black (FLX 985)

Technical.

- Minimum reccomended feature detail or wall thickness of 1mm.

- Temperature Resistance not published.

- Build Volume (Digital Materials, mixed Shore A values) 255 x 252 x 200mm

- Build Volume (Stand Alone, on demand) 490 x 390 x 200mm

Polyjet Rubber Like materials give designers a material with good flexibility and are ideal for use to confirm designs and proof of concept. However, continuous flexing may cause parts to shear or tear and flexibility may reduce over time and in cool environments.

Rubber Like Material Properties

Tango Black Plus (FLX 980) and Tango Plus (FLX930) - Stand alone.

- Temperature Resistance: Not published, expect low.

- Shore Hardness Scale A = 27

- Density 1.12 g/cm3

- Tensile Strength 0.8 - 1.5 Mpa

- Tensile Tear resistance: 2 -4 Kg/cm

- Elongation at Break 170 - 220%

- Compressive Set: 4-5%

- Water Absorption (D570-98 over 24 Hr) 1.15%

Agilus 30 (FLX 935 and FLX985) - Stand alone.

- Temperature Resistance: Not published, expect low.

- Shore Hardness Scale A = 30

- Density 1.14 to 1.15 g/cm3

- Tensile Strength 2.4 to 3.1 Mpa

- Tensile Tear resistance: 5 - 7 Kg/cm

- Elongation at Break 220-270%

- Compressive Set: 6-7%

Rubber Like materials, listed in columns by Shore A value.

Blended from Tango (Black) Plus and Vero White Plus:

|

Property |

ASTM |

Units |

Shore 40 |

Shore 50 |

Shore 60 |

Shore 70 |

Shore 85 |

Shore 95 |

|---|---|---|---|---|---|---|---|---|

| Tensile Strength | D-412 | MPa | 1 | 1 | 3 | 3 | 6 | 20 |

| Elongation at Break | D-412 | % | 160 | 140 | 90 | 60 | 55 | 30 |

| Tensile Tear Resistance | D-624 | Die C N/mm | 5 | 6 | 8 | 13 | 26 | 46 |

| Hardness Shore A | D-2240 | - | 40 | 50 | 60 | 70 | 85 | 95 |

We expect Agilus based materials to be better. Data to follow.

Common to Polyjet flexible materials:

- Tango and Agilus materials are built in 30um layers.

- Typical accuracy +/- 0.2mm depending on design, geometry and build orientation.

- Build Area: 255 x 252 x 200mm (490 x 390 x 200mm option)

- Minimum recommended wall or feature detail: 1mm

- Jet wash removed Wax like material support system.

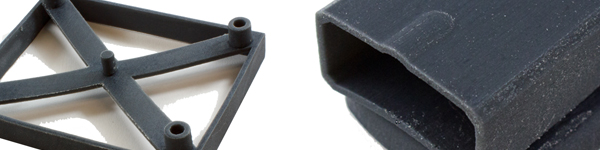

Examples of our 3d printing in Rubber.

3D Printed Materials

OUR CLIENTS SAY

Great news! I won the Young Engineer for Britain: Engineering Excellence Award at the NEC Big Bang Fair yesterday. I'd just like to thank you again for your generosity and your excellent prints. I'll be sure to recommend your company in future and I wish you all the best.

"Highly recommended as 3D-Alchemy are very helpful, efficient from design discussions through to delivery and take a great interest to provide us with the products we need."