Material Properties. 3D Printing.

Material Properties.

Here we have listed all our 3d printing material along with th key values for their main physical properties.

Data Sheets.

For most (but not all) materials we have dedicated data sheets published by their manufacturers with additional data. Let us know which you need and we'll email them over to you.

Important:

Please see the bottom of this page for notes and the small print on how to use the information.

Strong and Durable Materials

Ceramic 3D printing. SLA, Zirconia, Aluminia

Zirconia (ZrO2):

- True Technical Ceramic

- Temperature Resistance: 1500°C+

- Coefficient of Thermal Expansion: 10*10^-6 [1/K]

- Density 6.08 g\cm3

- Hardness HV10 1250

- Flexural Strength: 890Mpa

- Surface Roughness: Ra 0.3um

Alumina (Al2O3):

- True Technical Ceramic

- Temperature Resistance: 1650°C+

- Coefficient of Thermal Expansion: 8*10^-6 [1/K]

- Density 3.985 g\cm3

- Hardness HV10 1450 - 1800

- Flexural Strength: 430Mpa

- Surface Roughness: Ra 0.4 / 0.9um (2 versions)

3D Printed Zirconia and Alumina Datasheet \ Design guide.

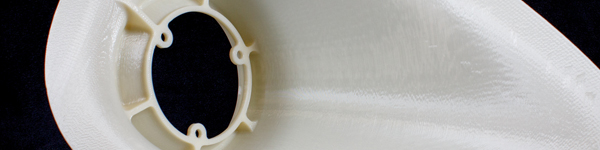

SLA Ceramic :

- SLA ceramic material built in 0.1mm layers.

- Temperature Resistance of 132°c. (268°c) HDT

- Density 1.61 g/cm³

- Tensile Modulus 10500Mpa (9800Mpa)

- Tensile Strength 68Mpa (80Mpa)

- Elongation at Break 1.1% (1.2%)

- Typical accuracy +/- 0.2mm depending on design, geometry and build orientation.

- Build Area - 500 x 500 x 590mm

- Break away support structure.

- Figures in brackets after a Thermal Postcure. Cost option, please request pricing) - Revised 6th December 2018.

Fine Detail

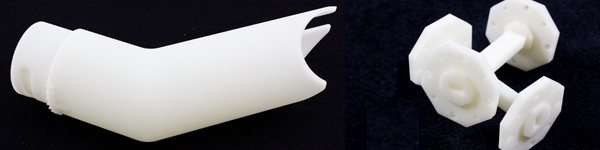

Flexible Materials

3D Printing service for printing LSR VMQ silicone.

Values depend on the Shore A value selected.

Silicone Rubber:

- Temperature Resistance: 200°c.

- Elongation at Break: 160%

- Tensile Strength: 2 to 2.5MPa

- Flexural Modulus: 68MPa

- Shore A Values: Shore A35

- Colours: Typically translucent white.

- Build Volume: 297 x 210 x 200mm

Click to download Silicone Rubber datasheet.

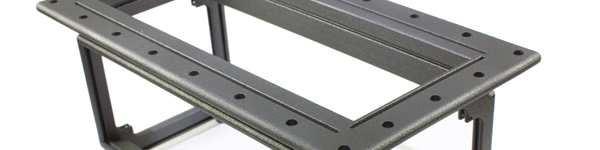

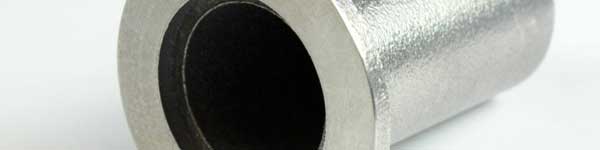

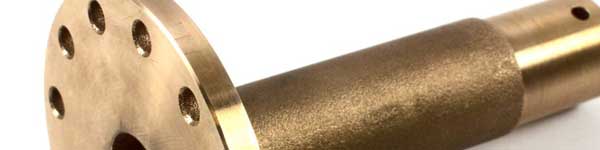

Metals

Stainless and Tool steels.

Build Area:

- 500 x 280 x 363mm

- 400 x 400 x 360mm

Data sheets to download:

Stainless Steel 1.4542 Datasheet (Coming soon.)

Stainless Steel 1.4859 Datasheet (Coming soon.)

The Small Print

All data has been provided by the manufacturers.

It was collected from specific specimens and test conditions and is provided for information only. Characteristics may vary if different specimens and test conditions are applied. Unless expressly provided in writing, no warranties are made and warranties of merchantability or fitness for a particular purpose are expressly disclaimed.

Body safe, Food Grade, Medical & Dental materials.

Generally materials are not 'Body Safe' or 'Food Grade'. In the Strong & Durable section, check Ultem for for FST, Bio Compatability or Food Safe applications. SLS PA2200 is also a possible candidate for food applications, plus 316L Stainless Steel.

The suitability of a 3D Printed part for a given application will depend on your design & should be proved by appropriate testing.

We make no guarantee or accept any resonsibility for the suitability of your selected material, design and finished 3d printed parts for your given application. We will strive to make your design to the best of our ability but you should endeavour to prove it's suitability & safety before use.

3D Printed Materials

OUR CLIENTS SAY

Efficient and useful service allowed me to test prototypes in aluminium. Discussion allowed concentration on important features for testing. Speed of delivery good. Would recommend.

"Very quick response, easy to deal with." (Rubber like 3d printed prototypes).