ABS ESD7. Electrostatic Discharge Safe. ESD Safe.

3D Print your designs in Static Dissipative ABS, ESD7.

Static Dissipative ABS (ESD7) is is a Electrostatic Discharge Safe or ESD Safe 3D printing material. Your choice for 3d printing designs for applications where static build up and resulting sparks is undesirable.

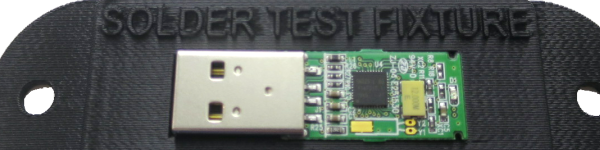

Our clients use our Static Dissipative material for jigs and fixtures to hold electronics during manufacture, storage devices for hard disk drives and production line components in environments where a spark could be dangerous.

ESD7 is 3D printed using the FDM process and is a very cost effective way of producing jigs, fixtures and guides which are strong, durable and still offer you Static Dissipative properties for ESD safe 3d printed parts.

Professional Materials.

All our FDM thermoplastic materials are made by Stratasys, the OEM 3D-Printer manufacturer.

This is important because we 3D print your designs from materials with a known manufacturing history. Each spool of ESD7 is Batch and Lot numbered and we can provide a Certificate of Conformity (COC) on request to confirm the material used.

Equally, using proprietary 3d printing materials means repeatability and consistent builds over batches of parts.

ABS ESD7 Static-Dissipative. Material Properties.

Key properties for our ABS ESD Safe 3D Printing:

- ABS plastic built in layers giving upto 80% mechanical strength for an injection moulded counterpart.

- Static dissipative for a Electrostatic Discharge Safe 3d printing material.

- Heat deflection temperature of 96c.

- Izod notched impact of 111 J/m

- Default print of 0.254 (254 Micron) layers.

- Minimum recommended wall or feature thickness of 1mm

- Build Volume: Max 406mm x 355mm x 406mm

For the full material properties for 3D Printed ESD-7 please see the material properties section -

3D Printed Materials

OUR CLIENTS SAY

"I was very impressed with the fast turnaround of fee quotes and production. David and his team provided excellent communication throughout and the items I ordered had excellent finishing. (ABS - Strong\Durable service) "

"Our customer in France wanted some 3D printed models for testing prior to ordering expensive mould tools. 3D Alchemy quoted, manufactured and delivered within 2 weeks. Highly recommend."