3D Printing. Ceramic.

3D Printing in our Ceramic materials gives your designs excellent temperature resistance, high strength and low conductivity.

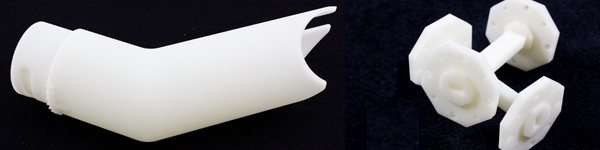

Another recent addition to our 'Strong & Durable' and 'Fine Detail' service, our Ceramic 3D printing service gives you an ideal material where you need Strength, Smooth surface finish and excellent temperature resistance. Designs produced in Ceramic can have fine detail and the off white colour enhances temperature resistance when exposed to local heat sources.

We give you two ceramic options, our original Ceramic infused SLA and true real technical ceramics in Zirconia and Alumina.

Our ceramics are not the traditional pottery process and do not involve kiln firing.

Technical Ceramics. Zirconia and Alumina

Zirconia and Alumina give you a choice of 2 true technical ceramics offering superb material properties including very high operating temperatures, hardness and electrical insulation.

Alumina offers best extraordinary hardness, is bioinert and has excellent corrosion resistance. Example applications include burner jets, laboratory crucibles and it's high dielectric strength makes it ideal as an electrical insulator.

Zirconia gives you low thermal conductivity and its tribological properties (low friction) make it well suited for sliding components and some medical applications.

Technical Ceramics:

- Zirconia or Alumina ceramic built with LCM technology.

- Temperature Resistance of 1650°c. (Alumina)

- Typical accuracy +/- 0.1mm depending on design, geometry and build orientation.

- Build Volume - 81 x 51 x 156mm (Alumina)

- Build Volume - 75 x 47 x 146mm (Zirconia)

- Break away support structure.

Ceramic infused resin (SLA)

Our original Ceramic 3D Printing service, based on laser curing a Ceramic infused resin material via the Stereolithography (SLA) process. The base liquid resin is cured layer by layer by a laser. Each layer is 100 micron thick and gives a nice smooth surface finish. We recommend that wall thickness or features in your design should be in excess of 0.5mm to ensure integrity.

SLA Ceramic :

- SLA ceramic material built in 0.1mm layers.

- Temperature Resistance of 132°c. (270°c) HDT

- Typical accuracy +/- 0.2mm depending on design, geometry and build orientation.

- Build Area - 500 x 500 x 590mm

- Break away support structure.

Material Properties.

Key properties for our Ceramic 3D Printed materials.

Zirconia (ZrO2):

- True Technical Ceramic

- Temperature Resistance: 1500°C+

- Coefficient of Thermal Expansion: 10*10^-6 [1/K]

- Density 6.08 g\cm3

- Hardness HV10 1250

- Flexural Strength: 890Mpa

- Surface Roughness: Ra 0.3um

Alumina (Al2O3):

- True Technical Ceramic

- Temperature Resistance: 1650°C+

- Coefficient of Thermal Expansion: 8*10^-6 [1/K]

- Density 3.985 g\cm3

- Hardness HV10 1450 - 1800

- Flexural Strength: 430Mpa

- Surface Roughness: Ra 0.4 / 0.9um (2 versions)

3D Printed Zirconia and Alumina Datasheet \ Design guide.

SLA Ceramic :

- SLA ceramic material built in 0.1mm layers.

- Temperature Resistance of 132°c. (270°c) HDT

- Density 1.7 g/cm³

- Tensile Modulus 10500Mpa (9800Mpa)

- Tensile Strength 68Mpa (80Mpa)

- Elongation at Break 1.1% (1.2%)

- Typical accuracy +/- 0.2mm depending on design, geometry and build orientation.

- Build Area - 500 x 500 x 590mm

- Break away support structure.

- Figures in brackets after a Thermal Postcure. Cost option, please request pricing) - Revised 6th December 2018.

Ceramic 3d printing.

3D Printed Materials

OUR CLIENTS SAY

"Great, trouble free service from a competent professional supplier. "

Great news! I won the Young Engineer for Britain: Engineering Excellence Award at the NEC Big Bang Fair yesterday. I'd just like to thank you again for your generosity and your excellent prints. I'll be sure to recommend your company in future and I wish you all the best.