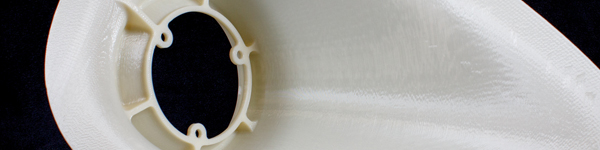

3D Printing. ABS M-30i

3D Printing & rapid prototyping in Bio Compatible ABS for medical applications.

Our bio compatible ABS M30i material gives you a cost effective way of producing parts which are strong and durable for medical and pharmaceutical applications.

The FDM (Fusion Deposition modelling) 3d printing process is used with the ABS M-30i material where material is heated and squeezed through a fine nozzle to build your design in 250 micron layers. The surface finish may be finely textured and slightly 'ribbed' where layers join and produces parts with robust mechanical properties, subject to your design.

ABS M-30i Bio Compatible \ Medical.

Our ABS-M30i material is Biocompatible ( ISO 10993 and USP Class VI.) and may be sterilised using either gamma radiation or EtO (Ethylene Oxide) methods.

M30-i is ideal where your applications need good strength and sterilization.

Colour: Ivory

Material Properties. ABS Bio Compatible.

Key properties for our ABS M30i Bio Compatible 3D Printing:

- Classification: ISO 10993 and USP Class VI.

- Strong: Typically upto 80% mechanical strength for an injection moulded counterpart.

- Heat deflection temperature of 96c.

- Izod notched impact of 128 J/m

- Default print in 0.254 (254 Micron) layers.

- Minimum recommended wall or feature thickness of 1mm

- Build Volume: Max. 406 x 355 x 406mm

For the full material properties for 3D Printed ABS M30i please see the material properties section -

3D Printed Materials

OUR CLIENTS SAY

"Quality of parts is nice for the first look (despite surface roughness of al-alloys impellers). Communication is almost perfect. Any technical notes are taking into account, any requirements of order can be discussed. Wide range of materials as I can say regarding metal alloys."

"Parts received. Quality is fantastic! Thank you for getting them all done so quickly. It makes a big difference to us this end."