3D Printing. Multi Jet fusion PA12

Our new HP Multi Jet Fusion MJF 3d printing process gives you Nylon PA12 parts with fine detail and excellent surface finish.

A new addition to our 'Strong & Durable' 3d printing service, our HP Jet Fusion3d printing service gives you an alternative to the traditional SLS process. The Jet Fusion process gives you parts with excellent temperature resistance, detail and surface finish. HP Multi Jet Fusion parts have been very impressive and we're proud to have been involved at the early stages of the development of the process.

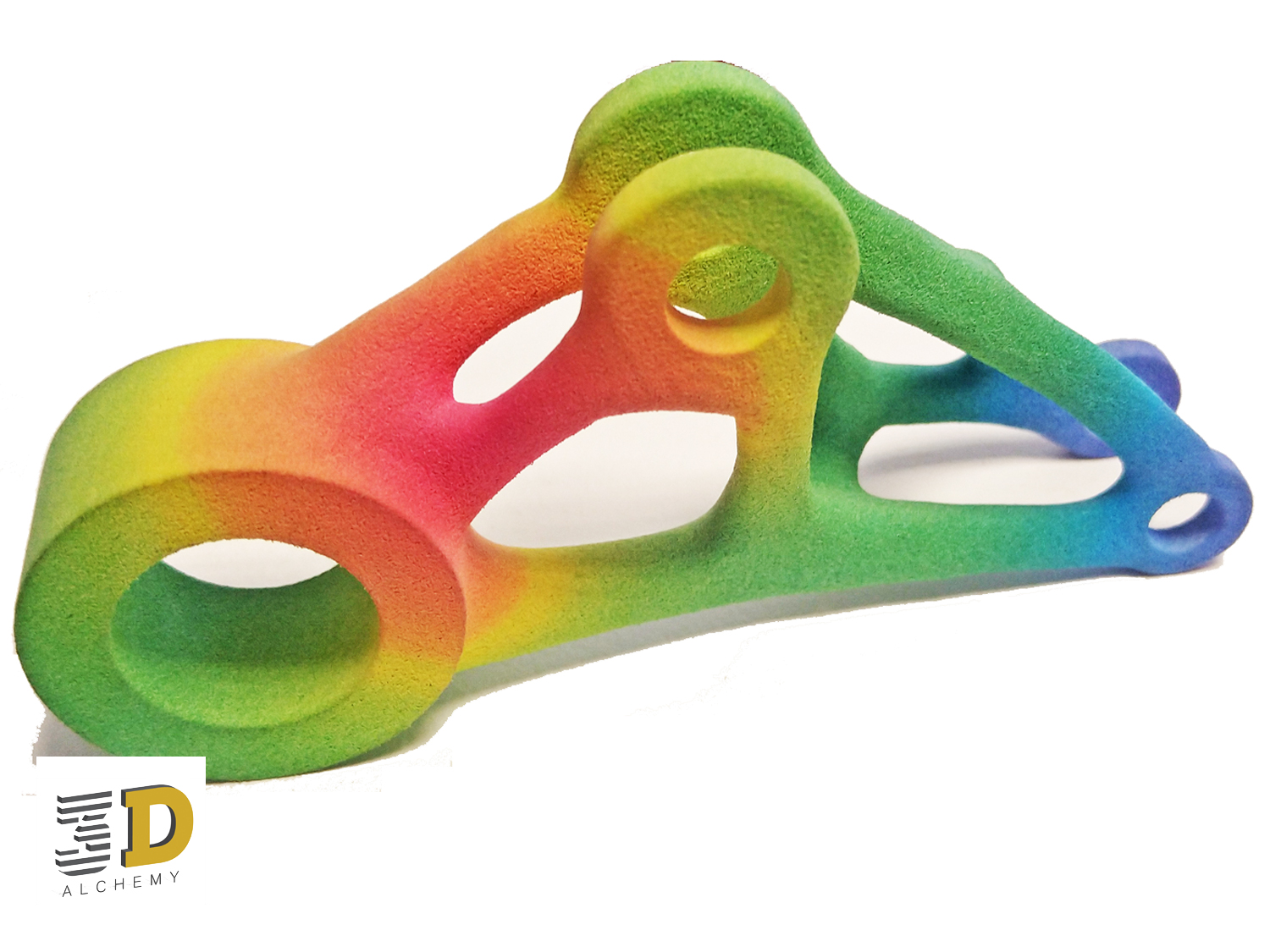

The HP Jet Fusion process brings fast build times and high material re-usability which gives you lower prices while still offering all the benefits of PA Nylon manufactured using traditional SLS processes. These include the ability to produce water tight parts while the self supporting powder allows for complex internal channels so simplifying support considerations.

The Jet Fusion process 3d prints your designs with an excellent build resolution of 1200 dpi in the x-y and a layer thickness of between 70um and 100um depending on machine configuration.

To summarise, The HP Multi Jet Fusion 3D Printed Nylon gives your designs:

High temperature resistance of 175 deg C. (Potential 'flash' resistance to 600 °C.)

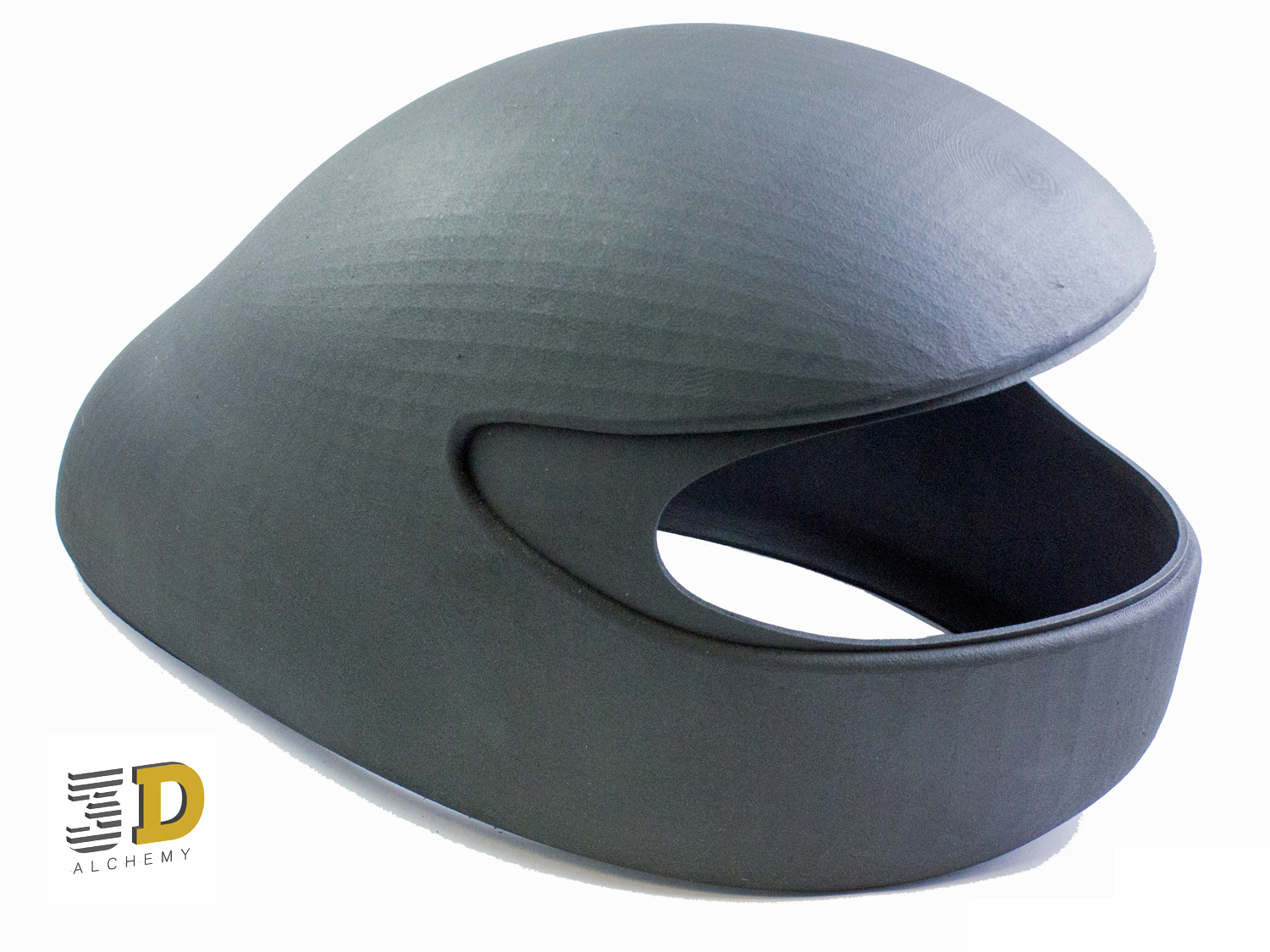

Excellent aesthetics in an 'Graphite Black' colour.

Fine individual details and wall thicknesses down to 0.8mm and less.

High levels of accuracy & dimensional stability.

Strength & Durability with robust material properties.

Excellent Chemical resistance to oils, greases, alkalies and aliphatic hydrocarbons.

Low cost per part.

Isotropic structure with minimal difference between x y and z layers and more freedom in part orientation.

Applications

The material and process are designed for batch runs of functional end use parts and prototypes. The self supporting powder is well suited to 3d printing complex assembles and lattice structures.

Jet Fusion Material Properties.

PA 12 (HP Jet fusion).

- Engineering grade material built in 70 to 100um layers.

- Temperature Resistance of 175 ºC. (HDT)

- Density 1.01 g/cm3

- Tensile Modulus 1700 Mpa

- Tensile Strength 48 Mpa

- Elongation at Break 20% (x,y) 15% (z)

- Typical accuracy +/- 0.2mm depending on design, geometry and build orientation.

- Build Area - 380 x 284 x 380mm

- Supporting Powder support system ideal for complex internal structures.

- Certifications: USP Class I-VI FDA , UL94, UL746A, REACH, PAHs and others

3D Printed Materials

OUR CLIENTS SAY

"Great company great service, very happy."

"The service was second to none. Fast response with a quote. Follow up emails keeping me informed of order progress and delivered exactly on time. Great quality of parts created from my cad drawings.....A great company to deal with. Quick and efficient service with great communication at each stage of the process. I highly recommend them and I would definitely use them again. It's the way all companies should operate."